The first automatic “zero setup” system to control your products.

PrimeCoMate is the machine vision system for quality control directly on the production line, capable of completely replacing human labor by taking the effectiveness and performance of supervision to new levels. Its performance is constant, repeatable and objective on 100% of production.

Thanks to PrimeCoMate, product inspection on your lines does not require pauses, is not subject to misjudgment or distraction, and is not limited to the single visual analysis adoptable by humans.

PrimeCoMate is “zero setup”: intuitive and immediately usable, it requires no configuration or setup and can be customized at any time to fit your tolerance meter.

COMPLETELY AUTONOMOUS!

It requires no user intervention.

That is why it is simple, fast and convenient.

PrimeCoMate, with its “zero setup” technology, can autonomously undertake the observation of production elements directly on the line.

Having acquired the basic data, PrimeCoMate initiates the proprietary processes of self-classification and, subsequently, self-learning necessary to effectively concretize its assessment.

When fully operational, the system works by exploiting the unsupervised learning method, using self-created knowledge through unique self-grading and self-learning procedures.

CUSTOMIZABLE AS NEEDED

PrimeCoMate also learns from you: with additional rules and customized criteria.

PrimeCoMate‘s flexible system allows you to change the severity of the judgments for the three main evaluation criteria (morphology, color and appearance) as well as to manually add control rules that will integrate with those forming the system’s automatisms, if needed.

This does not result in an overlap of different and potentially conflicting rules: In fact, PrimeCoMate can cascade the new rules, initiating a smooth “selection of selection” to optimize the effectiveness of your inspection.

Each additional rule allows you to teach the system, through supervised training, to recognize specic details or defects in the product under inspection. In this way PrimeCoMate will be able to:

- Detect the presence and quantity of such details or defects

- Derive the degree of integrity of such details

- Evaluate the severity index of such defects

THREE CRITERIA FOR A

VERDICT OF (IM)PERFECTION

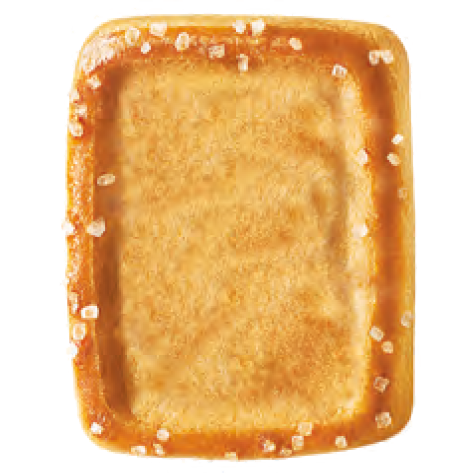

PrimeCoMate performs three categories of inspections:

MORPHOLOGICAL

Detects anomalies of shape

and size, breakages, deformations,

missing pieces etc.

CHROMATIC

Detects color variations,

finishing errors, composition

anomalies etc.

AESTHETICS

Detects imperfections

whatever their

appearance or size

PrimeCoMate’s innovative system makes in-depth analysis possible, because it creates a complete and comprehensive image of the product, which allows for the detection of every possible flaw. Thanks to deep learning, natural variations in the element do not interfere with the inspection, which is focused on detecting abnormal details not known beforehand.

THE ADVANTAGES OF PRIMECOMATE

PrimeCoMate manages itself by taking advantage of proprietary self-grading and self-learning procedures and therefore requires no programming or data entry by the user. Where a standard system would stop or make an error due to its inability to distinguish a natural variation from a defect, PrimeCoMate applies its own customizable tolerance criteria, dramatically reducing the number of false rejects. Moreover, this inspection system, thanks to self-learning and self-classification, does not require a translation of every categorizable anomaly into rules, and is moldable to individual needs, overcoming the narrow range of possibilities of other systems.

MORE SENSES FOR MORE CAPABILITIES

THE SEARCH FOR ANOMALIES IS FURTHER EXTENDED.

PrimeCoMate, with its “zero setup” technology, can autonomously undertake the observation of production elements directly on the line. Having acquired the basic data, PrimeCoMate initiates the proprietary processes of self-classification and, subsequently, self-learning necessary to effectively concretize its assessment. When fully operational, the system works by exploiting the unsupervised learning method, using self-created knowledge through unique self-grading and self-learning procedures.

HUMAN? NO, HUMAN-LIKE

It is not human, because it does so much more

What makes PrimeCoMate strikingly superior to the performance of a human being is its ability to:

- Leverage its proprietary technology to learn in total autonomy, applying the insights gained to quality inspection of products.

- Accurately distinguish product variations, ensuring accuracy in the exclusion of defective items and tolerance for acceptable anomalies.

- Refine their specific performance, through customization and “safe improvement on demand” systems that enable overall improvement.

But what makes PrimeCoMate non-comparable to a human being is its ability to:

- Impartially inspect every element, without yielding to subjective evaluations.

- Perform uninterrupted control, with a performance effectiveness not subject to the normal drops in performance of a human being.

WE CROSS THE FINISH LINE

WHY WE ARE CROSS-CUTTING

Our perspective is a set of viewpoints

Our vision systems will bring considerable benefits to your project, increasing performance are only in industrial but also in non-industrial areas. Our solutions solve problems related to the needs of those who need to make multiple and differentiated discernment procedures objective and repeatable: you.

Being transversal also means understanding your reality in its entirety by dialoguing with its different departments and providing solutions to the particular needs of each of them.